Today’s procurement leaders operate in an environment where complexity and risk are the norm. They must constantly juggle cost, capacity, and reliability, all while navigating shifting and unpredictable market dynamics, and unexpected disruptions.

Direct procurement is where these trade-offs play out in real time. It’s not enough to keep the production line moving either. Teams must ensure neither quality nor supplier relationships suffer – even in turbulent times.

In this blog, we’ll explore what direct procurement encompasses, how it connects with finance and the supply chain, and evolving best practices that drive long-term resilience.

Key Takeaways

- Direct procurement includes various connected processes that span early New Product Introduction (NPI) sourcing activities through the receipt of products and materials.

- Direct procurement shapes production resilience and supplier relationships.

- Balancing cost, risk, and capacity is crucial for operational and financial success.

- Scenario modeling and supplier diversification are vital best practices for procurement leaders.

| Learn how Ivalua can help you build a more resilient and aligned procurement function. Find Out More |

Why Direct Procurement Is a Strategic Function – Not Just Sourcing

Direct procurement encompasses the full scope of activities related to supply chain collaboration and the acquisition of goods essential to production. It is a core strategic function that directly influences an organization’s profitability and resilience.

Direct procurement teams work closely with finance, supply chain, and legal teams to help control margins, secure supply continuity, and mitigate risks across the business.

- For finance teams, direct procurement ensures that cost savings translate into real, bottom-line results – not just on paper, but across the entire product lifecycle.

- For supply chain teams, it helps align sourcing decisions with production schedules, demand forecasting, and logistics to keep operations running smoothly.

- Legal and compliance teams work with direct procurement to manage supplier contracts, navigating trade and regulatory challenges, and protect the business from costly liabilities.

- Engineering teams work with procurement to develop, ensure quality, launch, and optimize (e.g., Value Add / Value Engineering (VA/VE) activities).

To achieve this level of cross-functional performance, leading organizations rely on AI in procurement and integrated digital procurement platforms that can break down silos and provide a unified source of truth that enables effective collaboration effectively with stakeholders.

What Direct Procurement Owns and Why It Matters

Direct procurement owns the sourcing and management of raw materials, production-critical goods, and high-value supplier relationships—everything that keeps the wheels of production turning.

When direct procurement fails because of poor sourcing, contract mismanagement or supplier issues for example, the consequences are immediate. Organizations may experience stalled production lines or miss customer commitments and ultimately lose revenue. That’s why direct procurement is central to operational success.

How Direct Procurement Interacts with Finance, Supply Chain, and Operations

Direct procurement is tied to shared KPIs across finance, supply chain, and operations – for example cost of goods sold (COGS), inventory turns, and supply risk mitigation. Achieving these shared goals requires balancing each team’s priorities.

For example, finance may push for aggressive cost savings, while operations demand reliability and quality, and supply chain leaders focus on managing risk and flexibility.

When these stakeholders align, direct procurement becomes a lever for profitability and resilience; when they’re out of sync, tension can lead to bottlenecks and lost opportunities.

What’s Changed: Global Disruptions, ESG, and Resilience

The direct procurement landscape is evolving rapidly. Inflation and trade volatility are driving up costs, while nearshoring and regionalization reshape global sourcing strategies. Regulatory pressures are also rising, especially around ESG commitments and supplier compliance.

As a result, today’s direct procurement leaders must be agile enough to build resilient supply chains that can weather global disruptions and regulatory changes, while still meeting sustainability targets.

| Download our Procurement Platform datasheet to see how modern procurement technology can drive results for your team. |

Now that we’ve explored why direct procurement matters, let’s take a look at some key priorities direct procurement leaders must focus on to turn procurement strategy into execution.

Key Priorities for Direct Procurement Leaders

Direct procurement leaders face the dual challenge of protecting margins and ensuring operational continuity in our volatile world. Here’s how top-performing organizations turn strategy into action across supplier management, supply chain risk, quality and cost, and cross-functional collaboration.

Supplier Selection and Performance Tracking

Direct procurement leaders must go beyond simply choosing “strategic” suppliers. Supplier management software should have the ability to perform robust onboarding checks that include activities such as verifying financial stability, regulatory compliance, and ESG alignment.

Once suppliers are onboard, scorecards and performance metrics are essential for monitoring delivery times and quality standards. Audit-ready data ensures accountability and continuous improvement, even across global supplier networks.

Continuity of Supply and Multi-tier Visibility

In today’s environment, disruptions at sub-tier suppliers, such as a Tier 2 chip manufacturer, can halt entire production lines. That’s why direct procurement leaders prioritize visibility not just at Tier 1, but across every link in the supply chain.

Risk data along with supply chain risk management features like supplier dependency mapping and real-time monitoring help teams spot and mitigate issues early, ensuring continuity of supply, even in a volatile market.

Inventory, Quality, and Cost Alignment

Direct procurement leaders must work closely with supply chain teams to define inventory targets that protect margins and production flow, all while ensuring the goods meet quality specifications. Real-time insights and supplier collaboration help teams make smart tradeoffs, so no one has to compromise on what matters most.

Collaboration with Legal and Finance

Contracts, risk thresholds, and payment terms are areas that require procurement, legal, and finance to come together and collaborate. Automated workflows for contract approvals, built-in risk scoring, and clear processes for enforcing terms help remove friction and avoid delays.

When these teams work together seamlessly, direct procurement drives both compliance and value creation, and nothing slips through the cracks.

| Uncover the latest trends and best practices in strategic sourcing. Download the Ardent Partners report. |

While these priorities set the foundation for an effective direct procurement, strategic sourcing takes direct procurement to the next level. Here the focus is on upstream planning, long-term supplier relationships, and scenario-based category strategies that drive alignment and resilience. Let’s explore this critical component of direct procurement in more detail.

Strategic Sourcing for Direct Procurement

Strategic sourcing looks upstream, helping teams to build stronger supplier relationships, model scenarios for risk and capacity, and develop category strategies that go beyond short-term wins. Here’s how leading teams are putting these principles into practice.

Balance Cost, Risk, and Capacity

Direct procurement isn’t a one-size-fits-all approach. There are always inevitable tradeoffs between cost, risk, and capacity. Leading teams model scenarios to understand how supply risks and capacity constraints could impact operations.

For example, switching from a lowest-cost global supplier to a nearshore vendor might increase short-term costs but reduce long-term disruption and improve responsiveness.

These scenario-based insights help procurement teams make decisions that align with business priorities, no matter how the market shifts.

Leverage RFX, Negotiation, and Contract Data

The best strategic sourcing teams rely on data rather than instinct to make decisions. RFX events, negotiation history, and contract terms create a feedback loop that informs future sourcing decisions.

For instance, some sourcing modules automatically score supplier bids based on weighted factors such as cost, risk, and performance, empowering procurement to choose partners who deliver long-term value, not just short-term savings.

Nearshoring and Supplier Diversification

In a world where trade disruptions and geopolitical tensions abound, direct procurement teams are rethinking supplier location and diversification. Nearshoring and sourcing from regional partners can reduce delivery risk and improve agility, while insulating operations from unexpected policy changes:

- Proximity to Plants Reduces Lead Time Risk: Nearshore suppliers cut down transit times and reduce the impact of transportation delays, which is vital especially for production-critical goods.

- Regional Suppliers Reduce Exposure to Trade Policy Shifts: Regional sourcing minimizes the impact of tariffs, customs issues, and sudden policy changes.

- Diversified Sourcing Improves Contingency Planning: Using multiple suppliers in different locations adds backup options and flexibility – key for business continuity when disruptions hit.

| Download our strategic sourcing datasheet to learn how Ivalua can help drive better sourcing decisions. |

Despite the best planning, strategic sourcing comes with challenges – but the right procurement technology can help. In the next section, we describe some common blockers you may encounter, and how a robust digital procurement platform can help you overcome them.

Common Blockers Your Procurement Solution Needs to Address

Procurement teams face real challenges that can slow down progress and impact results. A modern direct procurement solution must address these issues to ensure success. Unfortunately, many fall short in the following ways.

Siloed, fragmented supplier data

When supplier data is scattered across different systems, there’s no unified view of supplier performance or risk. This lack of a shared foundation makes it nearly impossible to make data-driven decisions or manage suppliers effectively.

No Visibility Beyond Tier 1

Many procurement solutions stop tracking performance data at Tier 1 suppliers. But real risk often lurks deeper. Tier 2 suppliers can also face labor shortages or delivery disruptions, exposing you to hidden risks.

Misaligned Goals across Business Functions

Even the most advanced procurement tools can’t make up for teams within your organization (like finance, operations, and procurement) having conflicting priorities or goals. Finance teams might push for the lowest cost, while operations worry about reliability. Without shared data and visibility, collaboration tools and clear workflows, alignment is challenging and this can jeopardize success.

Overcoming these common pitfalls requires a powerful procurement platform with a specific set of features and capabilities. In the next section, we’ll cover what to prioritize when evaluating solutions.

What to Look for in a Direct Procurement Platform

Not all procurement software is created equal. Here are some key capabilities that set the best platforms apart from the rest.

Centralized Supplier Management and Onboarding

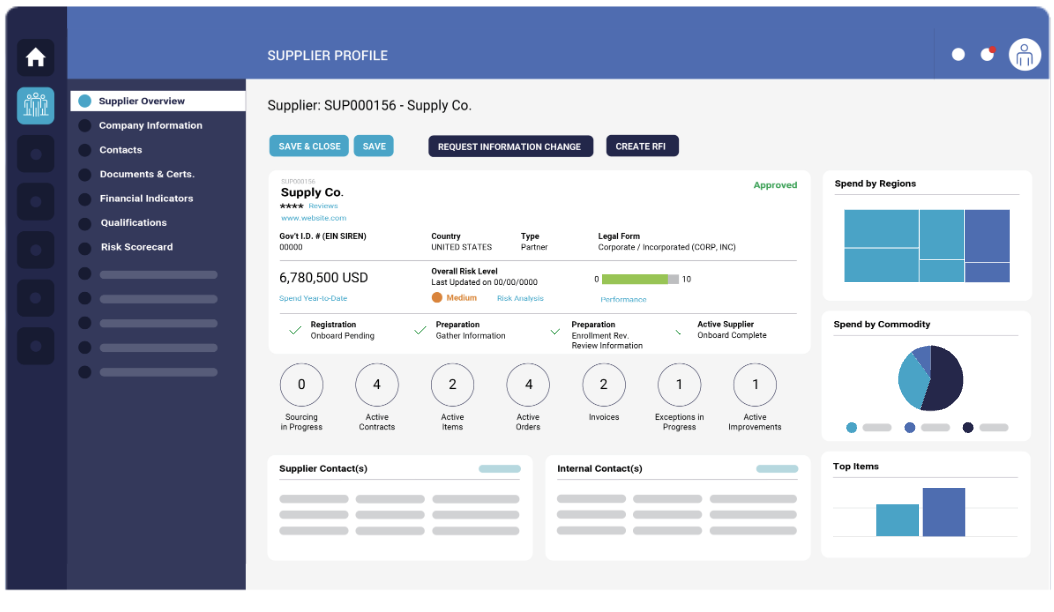

Centralized supplier management and supplier onboarding refers to having a single, unified system where you can store, manage, and update all information about your suppliers – everything from contact details and financial stability to performance metrics and compliance certifications.

Instead of scattered spreadsheets or disconnected tools, this central hub becomes your single source of truth for supplier information management.

Role-based access ensures that different users (procurement, finance, legal, etc.) see and can edit only the information relevant to their role. This keeps sensitive data secure while reducing confusion.

Integrated scoring is another key capability. A platform should automatically evaluate suppliers based on key criteria such as cost, risk, compliance, and past performance, enabling informed, data-driven decisions when choosing partners and managing supplier relationships.

Ivalua’s supplier management solution provides built-in supplier scoring, risk indicators, and secure access controls to empower procurement teams with the data they need to manage suppliers strategically.

Integrated Sourcing, Contracting, and Procurement

Traditional procurement often means juggling separate tools for sourcing events, contract negotiations, and day-to-day purchasing. Toggling between tools leads to data inconsistencies, duplicate work, and missed opportunities for optimization.

An integrated approach consolidates all of these activities onto a single platform, so you can manage sourcing events, contract terms, and purchasing workflows in one place.

A unified solution such as Ivalua’s Source-to-Pay platform reduces errors and administrative burden. Plus, it creates a seamless feedback loop, where data from contract performance, supplier negotiations, and purchase orders can inform sourcing decisions and support better alignment with business goals. It also helps organizations adapt rapidly to market changes.

Embedded analytics and risk scoring

Modern procurement decisions require real-time, data-driven insights, and the right platform will enable this in two important ways:

- Embedded analytics integrates analytical tools directly into procurement workflows, providing stakeholders with immediate access to relevant data without switching platforms.

- Risk scoring allows teams to automatically evaluate suppliers based on various factors such as financial stability, delivery performance, and compliance history.

This seamless integration ensures that decision-makers can take rapid action when needed, prioritize their actions, and back it all up with accurate, timely information.

Ivalua’s Spend Analysis solution offers embedded analytics that deliver real-time visibility into spend patterns and supplier performance. Its risk scoring capabilities assess suppliers across multiple dimensions, enabling organizations to proactively address vulnerabilities and optimize their procurement strategies.

Multi-ERP and supply chain system integration

Managing direct procurement across multiple ERPs and supply chain platforms is a complex challenge for any global organization, because each system may hold critical supplier, inventory, or order data. Without integration, information stays trapped in silos.

Such data fragmentation leads to inconsistent data, manual rework, and missed opportunities to optimize spend or supplier relationships.

A modern procurement platform unifies these systems by connecting ERP data with procurement workflows and supplier management, creating a single, accurate view of everything in one place. This helps to eliminate duplicate work and ensure consistent processes are followed across regions.

Ivalua’s multi-ERP integration capabilities connect seamlessly with multiple ERPs and supply chain tools, for centralized control and more efficient collaboration between global teams.

| Download the overview brochure to discover how Ivalua empowers procurement teams to drive strategic impact. |

Customer Story: How CACI Slashed Operating Costs by 30%

CACI International Inc. is a leading professional services and IT company serving the US federal government. Before Ivalua, CACI faced a fragmented procurement environment, including separate systems for PR, PO, invoicing, and payment. Users had to re-enter data repeatedly, while the financial ERP system failed to meet procurement and stakeholder needs.

With Ivalua, CACI gained complete visibility and control over its entire source-to-pay process. The platform enabled 99% of suppliers, digitized nearly all AP and purchasing activities, and brought 95% of spend under management. As a result, operating costs fell by 30%.

“Ivalua’s platform empowered us to realize virtually 100% paperless procurement and account payable processes. The ease of use and supplier friendly model delivered rapid value, and the flexibility helped bring our talent’s best ideas to life to build a competitive advantage.” – William Mertz Procurement Director, CACI

Read the full CACI case study.

Supercharge Direct Procurement with a Unified Platform

Direct procurement can be a cornerstone for operational stability and competitive advantage, but only if you have the right tools. A modern procurement platform can break down silos, automate compliance, and provide real-time insights to align cost, risk, and capacity decisions across teams.

By investing in the right solution, your organization can move from reactive problem-solving to proactive planning and innovation. With Ivalua, direct procurement becomes a strategic driver of value, turning your supplier data into a competitive edge that powers resilience and growth.

| Explore how Ivalua’s procurement platform can support your goals for direct sourcing.Watch Demo | Find Out More |

FAQs About Direct Procurement

What is Direct Procurement?

Direct procurement refers to the sourcing of raw materials, production-critical goods, and services essential to an organization’s core operations. It plays a vital role in ensuring supply chain stability and product quality.

How is Direct Procurement Different from Indirect Procurement?

Direct procurement involves buying materials and services that directly impact production. Indirect procurement covers goods and services needed to run the business (like office supplies or marketing). Direct procurement typically has stricter quality, delivery, and compliance requirements.

How does Direct Procurement support Business Continuity?

Direct procurement ensures that critical materials and components are available when needed to minimize disruptions and production delays. It also strengthens supplier relationships and builds resilience against market volatility.

What challenges do Teams face in Direct Procurement?

Teams often juggle competing priorities such as cost, risk, and capacity across global supply chains. A lack of visibility beyond Tier 1, supplier fragmentation, and cross-functional misalignment are common obstacles.

Can a Single Platform manage Sourcing, Contracts, and Supplier Data?

Yes, a modern procurement platform such as Ivalua can integrate sourcing, contract management, and supplier data into one system. This consolidation improves visibility, accelerates decision-making, and reduces risk across the procurement lifecycle.

Further Reading

Indirect Procurement: Why It Gets Mismanaged and How to Fix It

Direct vs Indirect Procurement: Key Differences, Challenges, and Opportunities