Direct and indirect procurement are two fundamental approaches in supply chain management, each serving distinct functions within an organization. Both focus on improving efficiency and reducing costs but differ in their strategic approach and impact on the core business operations.

Streamlining operations in indirect procurement helps maintain an agile and cost-effective organizational structure, while direct procurement emphasizes ensuring the quality and availability of key materials necessary for production. Together, these procurement strategies are essential for robust, efficient business operations.

In this blog post, we will explore the key differences and challenges between direct and indirect procurement, sourcing strategies that can be employed, and examine how technology can modernize these procurement processes.

Key Takeaways

- Unified sourcing platforms help connect planning, sourcing, and spend visibility for both procurement types, driving efficiency and competitive advantage.

- Direct procurement focuses on production-critical materials and suppliers, directly impacting margin and operational resilience.

- Indirect procurement supports organizational agility, requiring tailored controls and workflows to manage cross-functional spend.

| Discover how Ivalua can transform your direct and indirect procurement. Find Out More |

What Is Procurement?

An organization’s Procurement function is responsible for buying goods and services that are used to make the products sold to customers, and the purchasing of products and services used to run the organization on a day to day basis.

However, this is somewhat of an oversimplification of what the modern, best-in-class procurement organizations do for the larger business or organization. Procurement can and should be a significant value generator for the larger organization.

There are different phases of procurement value creation that tie into the Source-to-Pay process:

- Identifying Value: Procurement teams leverage spend data and spend analysis to understand trends in spend management, identify opportunities and develop category management strategies.

- Creating Value: Sourcing and procurement use relevant sourcing processes and tools to engage and select the best-fit supplier.

- Capturing Value: A contract is established that governs the responsibilities and obligations of both supplier and buyer, as well as when the organization has the right Procure-to-Pay processes in place, to ensure compliance to those agreements, goods, services, and prices.

- Monitoring and Measuring Value: The procurement organization takes a holistic view of the Source-to-Pay process and supplier relationships.

It’s important for procurement teams to do this across all spend categories, including direct spend vs. indirect spend, and to understand the differences and varying degrees of focus between each category of spend.d.

What Is Direct Procurement and How Does It Work?

Direct Procurement, or direct sourcing, is the end-to-end process organizations follow to manage the procurement of direct materials – any materials, parts, or components that are directly incorporated into the products being manufactured.

Typical Examples of Direct Procurement

Direct Procurement includes raw materials like metals, plastics, and chemicals; components such as semiconductors or mechanical parts; and goods for resale that are integral to a company’s core products. These materials and parts are the building blocks of a company’s final offerings, making them mission-critical to the manufacturing process.

Who Owns It in the Enterprise

Typically, direct procurement is managed by supply chain or operations teams. These teams work closely with product development, engineering, and quality assurance functions to ensure that the sourced materials meet precise specifications and production timelines.

In manufacturing environments, this ownership often starts in the new product introduction (NPI) phase, which encompasses product design, sourcing, quality testing, and launch. It continues through production and the product’s end-of-life phase.

Strategic supplier relationship management is also a key responsibility here, helping secure reliable supply and competitive pricing.

Key Challenges and Risks

Price volatility in raw materials and parts can eat into margins if you don’t manage them carefully. Not only that, quality issues can stall production and erode customer trust, and delivery failures can disrupt production schedules.

To avoid these pitfalls, supply chain and procurement leaders should continuously monitor risk, strengthen supplier relationships, and work to mitigate disruptions through planning and cross-functional collaboration.

What Is Indirect Procurement? Key Categories and Dynamics

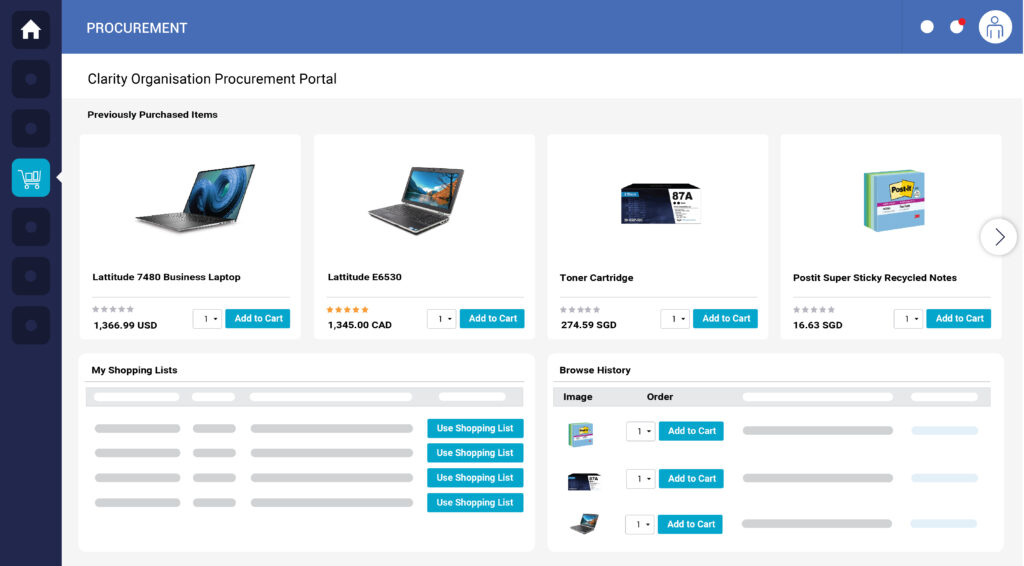

Indirect procurement involves acquiring goods and services that are not directly tied to manufacturing inputs but are essential for day-to-day operations – from IT hardware and office supplies to consulting services and facility management.

Unlike direct procurement, which typically has a more centralized and production-focused approach, indirect procurement tends to be more decentralized, with multiple departments such as IT, HR, and facilities driving purchase orders and purchasing decisions.

This cross-functional spend profile makes effective management vital, so employees have the resources and services they need to stay productive.

Common Categories of Indirect Procurement

This category of spend includes office supplies, maintenance services, IT services and software, utilities, and facility management. It also includes travel and consultant spend.

Why Indirect Spend Is Harder to Manage

Indirect spend is notoriously challenging to control because it involves many different stakeholders across the organization, each with their own needs and priorities.

Unlike direct procurement, which is usually owned by supply chain or operations, indirect spend decisions are spread across various departments, leading to lower visibility, inconsistent processes, and less adherence to procurement policies.

Key Compliance and Cost Risks

Poor control over indirect spend can introduce significant risks. Maverick spend – purchases made outside of approved channels – can quickly balloon, wasting budget and exposing the organization to unvetted suppliers.

Contract non-compliance is another concern, as departments may bypass negotiated agreements and miss out on better terms.

Direct vs. Indirect procurement: Key Differences at a Glance

Let’s examine some of the major differences between direct and indirect spend in more detail.

The table below offers a summary of these main differences.

| Focus Area | Direct Procurement | Indirect Procurement |

| Purpose of spend | Securing goods and materials critical to production | Supporting day-to-day operations and services |

| Examples | Raw materials, components, packaging, production equipment | Non-production goods like office supplies, IT services, marketing, travel |

| Primary stakeholders | Manufacturing, supply chain, finance, operations | Facilities, HR, marketing, IT, finance |

| Procurement process | Forecast-driven as part of production planning | Request-driven, ad hoc based on operational needs |

| Risk exposure | High: impacts production continuity, margin, quality | Lower: impacts efficiency, but not production |

| Maverick spend | Generally lower due to strict oversight | More frequent as end-users make ad hoc purchases |

| Systems and controls | Integrated with ERP, MRP, and supplier collaboration tools | More varied: P2P systems, operating expense management tools |

Learn how Ivalua’s AI-powered procurement platform can help you manage both direct and indirect spend.

Spend and Supplier Differences

Direct procurement primarily aims to secure the best quality materials for production at the most cost-effective price to maintain, or improve product quality and ensure the production process is economical and efficient. Managing risk and ensuring supplier reliability is crucial to avoiding supply chain disruptions in the manufacturing process.

Indirect procurement focuses on minimizing costs while ensuring that the organization has all necessary support services and supplies for smooth operations. Efficiency, cost savings, and operational effectiveness are typically prioritized over the strategic relationships that characterize direct procurement.

Stakeholder and Process Variation

Direct procurement involves supply chain ownership, requiring tight collaboration with the production department, quality assurance, engineering, and product development teams. Suppliers in this area are typically considered strategic partners, and these relationships are actively managed for long-term cooperation and value.

Direct procurement also typically follows a more structured process due to the high stakes associated with production continuity and quality. This process may include detailed supplier assessments, quality checks, and long-term contracting to ensure reliability and consistency in the supply chain.

In contrast, indirect procurement is more distributed, engaging a wider range of stakeholders from across the organization, such as IT, facilities, HR, and finance. Supplier relationships in indirect procurement tend to be less intensive unless the service is mission-critical, like IT support or essential facilities maintenance.

Indirect procurement often involves more transactional and routine purchasing activities. The focus is on streamlining operations and reducing costs through methods such as bulk buying and vendor management and consolidation.

Procurement Controls and System Needs

Tooling needs for direct vs. indirect procurement are also different:

- Direct procurement requires robust Bill of Materials (BOM) tracking and traceability systems to ensure accuracy in sourcing and production.

- Indirect procurement benefits from automated workflows, guided buying, and budget controls to keep spend within approved parameters.

Learn more about how Ivalua’s no-code/low-code AI-powered Procurement platform can transform your procurement operations. Get the datasheet!

Now that you understand the differences between direct vs. indirect procurement, let’s learn about the implications of each type of spend.

The Strategic Implications of Direct vs. Indirect Procurement

Each type of spend has unique implications for margin, operational efficiency, and enterprise-wide planning.

Impact on Margin, Delivery, and Risk

Direct procurement plays a central role in determining your cost of goods sold (COGS), which directly influences your margins and overall profitability. It also affects production schedules and supplier risk. If direct materials aren’t sourced effectively, manufacturing delays or quality control issues can pop up, delaying timelines and potentially damaging customer satisfaction.

Operational Efficiency and Cost Control

While indirect procurement doesn’t directly impact product margins, if poorly managed, it can inflate administrative costs and limit your ability to adapt to new market conditions. It can also expose you to compliance risks.

When managed well, indirect spend can be a key driver of operational agility, enabling your team to stay focused on core tasks rather than getting bogged down by inefficient processes.

Planning and Reporting Challenges

The differences between direct vs. indirect procurement also mean they require distinct approaches to KPIs, governance, and procurement system configuration.

- Direct procurement usually involves predictable, forecast-driven planning cycles.

- Indirect procurement often relies on ad hoc requests and rapid responses to changing needs.

This variation demands tailored data models, workflows, and reporting structures – otherwise, procurement teams risk misalignment with broader enterprise goals.

See how your systems support direct and indirect procurement types at scale. Get our checklist.

Next, we’ll explore how direct and indirect procurement can help your organization achieve its business goals.

Where the Biggest Opportunities Lie for Both Procurement Types

Both direct and indirect procurement have unique challenges – but they also have untapped opportunities. Here’s where the right strategies and the technology can unlock value.

Direct Procurement – Strengthen Supplier Continuity and Cost Control

There are several ways to create value in direct procurement:

- Leveraging volume in direct procurement can help secure better pricing and reduce supply risk.

- Implementing multi-tier risk tracking helps spot vulnerabilities further down the supply chain, reducing the chance of disruptions.

- Inventory-linked sourcing strategies ensure you’re not overcommitting or leaving gaps that could impact production.

Indirect Procurement: Driving efficiency, visibility, and compliance

Indirect procurement is typically more fragmented and less visible, creating opportunities to tighten control and drive compliance:

- Guided buying features make it easier for employees to choose approved suppliers and stay compliant.

- Approval workflows ensure that spend stays within budget and policy limits.

- Capturing off-contract or “maverick” spend provides visibility into gaps and opportunities for consolidation.

Unified opportunity: Connecting planning, sourcing, and execution

The biggest opportunity is to close the loop between planning, sourcing, and execution by managing both types of spend together. When budgets, forecasts, sourcing activities, and actual spend are fully connected, procurement teams can make smarter decisions, reduce maverick spend, and align with broader financial and operational goals.

Access the Procurious Next Level Procurement Report to unlock expert insights and fuel your procurement strategy.

One organization, Körber, has successfully unified direct and indirect spend management, using Ivalua.

Customer Story: How Körber Manages all Sourcing on One Platform

Körber manages several companies across five business areas – Digital, Pharma, Supply Chain, Tissue and Tobacco, and maintains 100 international locations. The procurement team was managing procurement with multiple ERP systems, which left a lot of room for improvement in supplier collaboration and communication.

The team came to Ivalua in hopes of improving traceability, optimizing spend, simplifying the IT infrastructure, and unlocking more value from suppliers.

Körber used Ivalua to create a central, flexible, and fully integrated S2P system that can drive consistency globally while meeting unique Business Area requirements. With a single platform, they can manage all sourcing activities – direct and indirect – and leverage end-to-end collaboration to bring suppliers and internal stakeholders together. They now have a unified data model to support true 360-degree visibility of suppliers worldwide.

“The Ivalua platform enables us to manage all major sourcing activities [direct and indirect] in one place, driving standardization and supplier data harmonization across our global businesses”

– Michael Stietz, SVP & Chief Procurement Officer, Körber

Read the full case study.

Sourcing Strategies for Direct and Indirect Procurement

To ensure your procurement strategy is delivering maximum value, it’s essential to actively seek out opportunities for improving both direct and indirect spend management. This means analyzing spend data to uncover cost-saving opportunities and eliminate redundancies.

For indirect procurement specifically, supplier performance must be tracked holistically. Unlike direct procurement, indirect spend typically covers a broad range of categories and stakeholders.

Establishing the right Key Performance Indicators (KPIs) is critical to measure and guide supplier performance. The most important ones are:

- Cost Savings: Measures reductions in total spend compared to prior periods — often through better contract negotiations, strategic sourcing, or process efficiencies.

- Purchase Order Cycle Time: Tracks how long it takes from creating a purchase order to fulfillment, helping identify bottlenecks and improve responsiveness.

- Supplier Compliance Rate: Assesses how well suppliers adhere to the agreed-upon terms and service levels in contracts, ensuring contract value is fully realized.

- Contract Utilization: Measures what percentage of spend flows through existing negotiated contracts—highlighting whether your organization is leveraging these agreements or bypassing them.

- Maverick Spend: Tracks off-contract or “rogue” purchases, pinpointing areas where spend control is lacking.

- Supplier Lead Time: Evaluates how quickly suppliers deliver once an order is placed, providing insight into the reliability of your supply base.

- Procurement ROI: Calculates the return on investment by comparing the savings and value generated against the costs of running procurement operations.

- Supplier Risk Management: Gauges how effectively procurement teams are identifying, assessing, and mitigating risks—such as supplier financial health, regulatory issues, or geopolitical threats.

It’s equally important to work closely with internal stakeholders to ensure these KPIs align with wider business goals. Modern technology platforms, such as e-procurement tools and AI-driven analytics, can help turn these insights into action.

Platforms like Ivalua are transforming how organizations handle both direct and indirect procurement by standardizing workflows and empowering smarter decision-making.

See how streamlined, intelligent procurement can support your team’s performance and growth: view brochure.

Why Sourcing Strategies Must Differ

Direct and indirect procurement have distinct operational realities and therefore require tailored sourcing strategies.

- In direct procurement, consistency is king. Volume commitments, delivery windows, and supplier reliability are essential to keeping production lines moving and meeting customer demand.

- Indirect procurement, on the other hand, is characterized by decentralized decision-making and dynamic, shifting needs that vary by department or location. Here, procurement teams must balance standardized controls with flexibility to serve diverse stakeholders and evolving requirements.

When to Centralize vs. Decentralize Sourcing

Finding the right balance between centralized control and decentralized agility depends on several factors. Executives should ask:

- How critical is the category to production or service delivery?

- Are supplier markets fragmented or consolidated?

- Do end users require specialized input or support?

Centralized sourcing can deliver volume discounts and standardized quality for high-value categories, while decentralized approaches often work better for services or low-volume purchases that need to adapt to local needs.

The Role of Data, Collaboration, and Tech in Execution

Whether sourcing is centralized or distributed, procurement leaders need accurate data, tight cross-functional collaboration, and flexible technology to execute effectively.

Integrated tools like Ivalua’s sourcing solution enable you to align sourcing strategies with real-time demand signals, supplier risk profiles, and cost drivers, ensuring decisions are informed, strategic, and accountable.

By breaking down silos and providing a single source of truth, procurement teams can adapt to changing business needs while delivering measurable value.

Explore Ivalua’s Strategic Sourcing Report to uncover actionable insights and drive smarter procurement decisions. Download now.

Gain Operational Resilience with a Unified Procurement Platform

Effectively managing direct and indirect procurement requires understanding their distinct impacts, using the right KPIs to measure success, and leveraging strategic procurement software. By implementing these practices, your team can make more informed decisions and control costs, while maintaining compliance throughout the procurement cycle.

Unified procurement platforms like Ivalua transform sourcing and payment processes into sources of operational resilience and strategic advantage, enabling organizations to respond nimbly to change and stay ahead in today’s competitive landscape.

Explore Ivalua’s procurement software and elevate your procurement process starting now! Watch Demo | Find Out More

FAQs about Direct vs. Indirect Procurement

Why does it matter who owns each type of spend?

Ownership impacts everything from strategic alignment to risk management. Direct procurement typically sits with supply chain teams who can directly influence production outcomes. Indirect procurement, by contrast, involves many departments, requiring tight governance to keep costs in check and avoid duplication.

Can one platform manage both types effectively?

Yes. A unified platform can support both direct and indirect procurement by standardizing processes, ensuring clear data visibility, and adapting to the unique needs of each type of spend. This enables teams to streamline sourcing, track savings, and maintain compliance across the board.

How should savings be tracked differently for direct and indirect procurement?

Savings in direct procurement are usually tied to unit costs, supplier continuity, and inventory management, which is critical for manufacturing margins. Indirect savings focus more on reducing maverick spend, consolidating suppliers, and improving compliance – all essential tasks that help organizations manage overhead and operational costs.

What’s the risk of managing both procurement types in siloed systems?

Siloed systems create data gaps, duplicate work, and misaligned strategies. For direct procurement, this can disrupt supply and impact production. For indirect procurement, it can mean higher costs, lost savings, and poor compliance. An integrated platform bridges these gaps for visibility and control.